UTM Tallinn

UTM Tallinn:

Ultrasonic thickness measurements (UTM Tallinn) for all type of vessels including ESP

– class survey

– intermediate survey

– CAP

– steel condition assessment

– steel supervision

– draft reports at sea during a voyage

– calculation of steel renewal weights

The main direction UTM Tallinn:

- pre-repair defectation of hull structures, pipelines and pressure vessels on ships and floating structures with measurements of residual thicknesses with a detailed examination without decommissioning, as well as during repair

- technological support for the repair of the vessel’s hull, control over the quality of welding and the amount of metal replacement

- development of Extended examination Programs

- forecasting the volume of repair of the exterior cladding based on the results of previous defects

- calculation of the actual general and local strength of ship hulls

- analysis of the causes of damage to hull structures of ships and recommendations for their elimination

- inspection of vessels during their purchase/sale

Coating inspection

We also monitor the condition of the surface both at the transition and in the dry dock. All inspectors have the necessary working qualifications and experience. After the inspection, we provide a full report on the inspection of this part together with

recommendations.

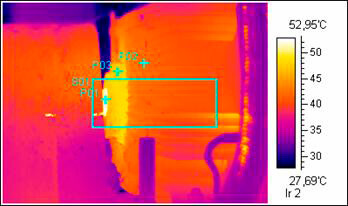

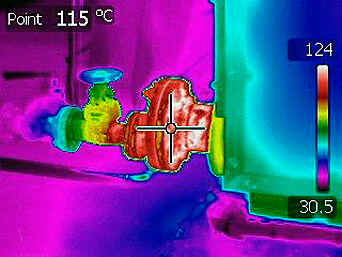

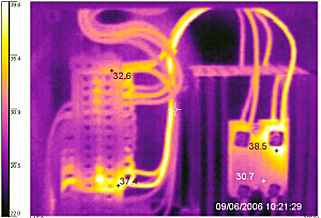

Thermography

We use a unique instrument that uses the infrared part of the light spectrum, which is invisible to the naked human eye. Infrared, thermographic, or as it is sometimes called thermal scanning, allows you to see the inspected objects in daylight or without it.

Marine thermographic survey of electrical systems of ships includes:

- inspection of main switchboards

- emergency switchboards

- engine room control panels

- switchgear

- switchboards, and other equipment

- emergency generator and battery systems

Advantages of thermography:

- it is a non-contact way of analyzing various areas, environmentally friendly and safe for personnel

- the 2D nature of testing allows you to obtain thermographic profiles at one or more points on the same image

- it is performed in real time, quickly, which significantly reduces the diagnostic time

- significantly reduces the examination time compared to other methods

- reduces the final cost of any repair, since there is no need to disassemble any of the components being tested. This method accurately identifies problems where they occur, and even before these defects become apparent to the naked eye

Rope access

In the Marine and Offshore Industry, application of rope access includes Hull Thickness Gauging, Close-Up inspection of vessel using CCTV system, lifting Gear Inspection, Anode Replacement, derrick and Crane Inspection, Conventional and advanced Non-Destructive Testing (NDT) techniques, Structural Condition Surveys, Maintenance and Mechanical jobs.

Our rope access team members are trained and certified as IRATA ( Industrial Rope Access Trade Association) Level III, Level II and Level I and they assure you safe inspection, testing and structural surveys at height or in areas where access is difficult.

Anchor Chain Calibration

Our team of specialists also provides, if necessary, the following service

Where considered necessary, joining shackles and other cable fittings should be gauged at their point of greatest weardown. Consideration should be given to replacement when the wear down equates to 12% loss of diameter over original.

Supervision

We supervise steel and paint works during repairs in the shipyard or in voyage repair.

- welding inspection

Visual inspection

During the inspection process, we also provide a general understanding of the condition of the metal structure as a whole, including the condition of the welds and bearing joints. If necessary, we prepare a photo and video countdown, which significantly saves the crew time during subsequent inspections.

Voyage repair

We are fully equipped to perform any kind of repair work and have the capability to deploy an experienced team, anywhere you might need it, guaranteeing the best possible service and highest quality repairs.

Vibration analysis

Vibroacoustic measurements and tests: vibration measurement. Our company’s specialists measure the vibrations of mechanisms and equipment with the provision of a test report using a vibration analyzer. The maximum permissible vibration levels are regulated by the Rules of Classification and Construction of Marine Vessels. Vibration analysis of mechanisms is a type of equipment defect that does not require its dismantling and disassembly.

Ultrasonic Tightness Testing

One of the primary concerns in the shipping and related industries is the damage sea water can inflict on a ship’s cargo, often leading to costly insurance claims for shipping companies. Ultrasonic leak detection offers a quick and reliable solution for assessing and testing the integrity of hatch seals and doors, ensuring they are secure against weather conditions and reducing the risk of such incidents.

Applications of leak detection equipment:

- Evaluate the tightness of cargo hatch covers on bulk carriers

- Inspect seals in areas such as bow, side, and stern doors, or any openings requiring secure sealing

- Perform integrity tests on watertight doors (WTDs)

- Test the tightness of closing appliances or compartments